Wearable and mobile products come with a number of challenges in controlling temperature and achieving the comfort temperature goal. The following text delves into how thermal simulation observations are concretized into design solutions and ultimately refined into higher quality products from user experience.

The normal way to use wearable and mobile devices is to hold them against the skin for long periods of time. Metal exterior parts feel hotter than plastic parts due to their better thermal conductivity. Wireless charging pads, in turn, may unnecessarily heat the device. The compact size and power density of the devices contribute to raising the bar for design. Simulation can be used to model thermal behavior up to the precision point with respect to the insides of the component.

Safety and comfort are the starting points of thermal design

The basic premise of product and thermal design is that products are designed to be safe for the user and are of high quality for the user. In mobile consumer electronics, such as tablets, smartphones and smart bracelets, the temperature application ranges are rather limited in normal use from 0 to 35°C.

As a rule, no lower limit is specified for equipment surface heat, but the maximum value is often considered to be +48°C (IEC 62368-1:2020). However, for the most common usage cases of equipment, the objective is to remain within so-called comfort heat limits. These comfort heat limits vary, depending on the surface materials of the device and the body part concerned. For example, the ear is more sensitive to heat than the palm of the hand. We have research data on general limits used and surveys conducted according to user surveys.

Thermal design objectives

In principle, the object of monitoring in thermal simulation is surface heat specific to various components and materials. Thermal simulation has two objectives:

- To achieve comfortable surface temperatures (thermal comfort) for the most common cases of use.

- To ensure that device temperatures remain below the safety limits prescribed by the standards.

Are you interested in thermal simulation? Download our guide and read more about the benefits of thermal simulations in your product development projects!

Wrong operating temperatures increase equipment interference

If you look at temperatures somewhat higher than comfort temperatures, it can be observed how various electronic components start to be affected by disturbances as a result of temperature increases.

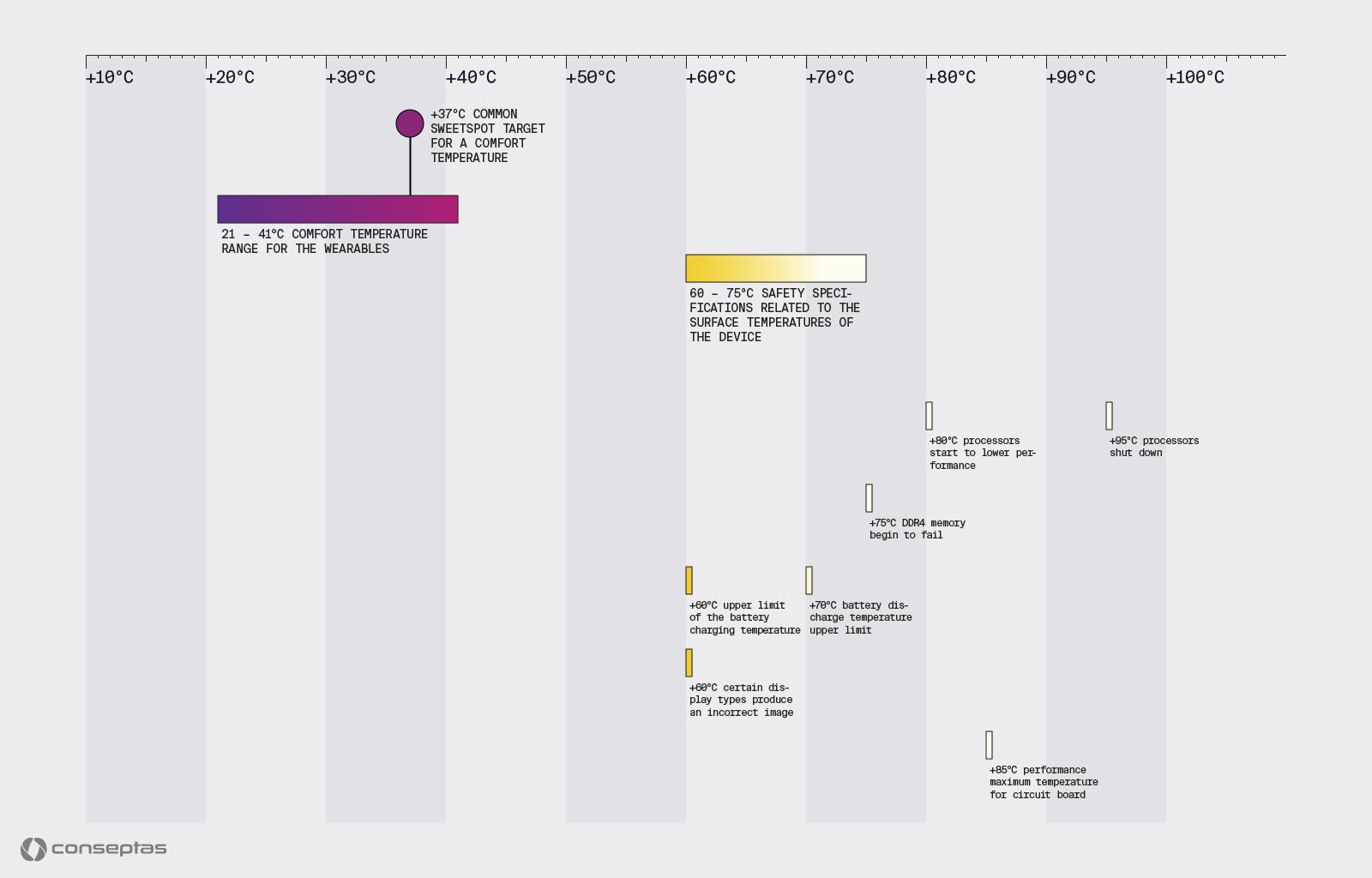

For example, processors used in mobile devices start dropping power at +80°C and may have to turn themselves off at +95°C. DDR4 memories may begin to produce errors when they exceed the +75°C temperature limit. For instance, faults occur as errors in writing to memory when, i.e., incorrect information is entered while shooting a video; or the entire processing file can be corrupted.

There are slight differences in temperature limits between battery technologies, but, e.g., a Li-ion battery commonly used in mobile devices is not allowed to be charged above +60°C and must not be discharged at temperatures above +70°C. Excessive heat depletes battery capacity and shortens its life, so it is good to keep the battery-operating temperatures at below +50°C.

Certain display types and camera sensors generate noise to the image at +60°C and are sensitive to large thermal distribution. PCB materials are usually specified for a +85°C performance maximum, though their actual tolerance moves in the range from 100 to 135°C, depending on the insulation material used.

Comfort temperatures for wearable and mobile devices are limited to 21-41°C. The diagram shows general limit values for the operation of key components.

Sensitive components can be heated under cold conditions. However, for mobile devices, this is rare, since heating consumes the battery. At cold temperatures, either battery capacity is not made available other than to a small degree or the safety circuit prevents the battery from being used completely. Certain display technologies do not work well cold.

Many common technologies may suffer from thermal issues

Many technologies used in mobile and wearable devices may show heat problems. Potential equipment meltdowns or scorches are often the result of poor design, manufacturing defects, or failure during operation.

For example, wireless charging occurs via a copper thread and the coil heats inductively during charging. As coil heats up, the parts and components around it may also become heated. The typical challenge is that the charging coil is close to the battery and it otherwise uselessly heats the cell from the charging current.

The configurations of mobile devices today make very large use of glues and adhesive tapes. These are usually not damaged due to the device's own heat dissipation, but their failure may be the result of heat exceeding the limit value from external sources, such as sunshine. We can simulate a situation where, for example, the phone has been forgotten directly under intense solar load on the dashboard of a car.

Thin devices are challenging in terms of thermal control

For very thin devices, it is difficult to find good solutions for temperature control. When the device is thin, heat easily enters the surface of the device. At that point, the user feels the heat and heat distribution is already too late.

In a looser configuration, the aim is to spread the heat as wide as possible over an area from which it can be reached by convection (i.e., the transfer of heat in a gas or liquid along with heat induced currents) or radiation away from the device. In practice, heat is also transferred to the user in mobile devices, but when heat is applied over a large area, the user no longer reacts to it as hot. A product with an even temperature is more comfortable than a device that has some hot spot.

Tips for thermal design

Lastly, from the point of view of a thermal engineer, we offer a few tips for electronics and mechanics designers as well as for industrial designers:

- Position components in as wide an area as possible. It makes things easier for local hot spots.

- Split the heat-sensitive components further away from the hot components.

- Check the component specifications to see if the component is cooled through the top or through the circuit board.

- Metallic finishes feel hotter to the skin than plastic/wooden ones, but they also spread heat more efficiently.

- Applying heat as close as possible to the heat source is the most efficient way to obtain the smallest possible difference between individual surface temperatures.

- Detailed information on the temperature limit values prescribed by the standards can be found in SFS-EN IEC 62368-1:2020 Audio/video, information and communication technology equipment - Part 1: Safety requirements